Secure Seal® 3”-24” Diameters (SS, SSD, SSID, and Flex)

QUALITY AND DEPENDABILITY

The Secure Seal flue is manufactured from either 316L or 29-4C, a super-ferritic stainless steel designed for extreme resistance to chloride ion pitting, crevice corrosion and stress corrosion cracking, as well as general corrosion in oxidizing and moderately reducing environments. 29-4C and 316L are the ideal choice for withstanding the harmful effects of corrosive condensates created by partially or fully condensing high-efficiency natural gas and propane-fired heating appliances.

The Canadian Gas Research Institute found that test results proved 29-4C to be one of the two “most corrosion-resistant alloys of 20 candidate stainless steels evaluated for resistance to chloride-induced corrosion in condensing and partially condensing gas-fired appliances.”

STRINGENT STANDARDS FOR QUALITY ASSURANCE

To guarantee a perfect fit every time and to avoid built-in stress points or weak areas, tube ends are formed under stringent guidelines and held to exacting standards.

The casing (outer tube on Secure Seal SSD/SSID) is manufactured from type 441 stainless steel to provide long-lasting performance and stability when exposed to the outdoors.

The air space between the flue and casing is 1″ on SSD and 2″ insulated on SSID, providing close clearances to combustibles, reasonable outside dimensions and an additional heat shield or margin of safety where needed.

BUILT TO LAST

Secure Seal features a smooth weld seam inside and out, which is completely shielded during the welding process. Contamination or molecular changes in the weld seam are avoided and no fillers are used in the welding process.

The Secure Seal double-wall system is fully interchangeable with our Secure Seal single-wall system. Both have been conformed to UL1738 and certified to ULC-S636 safety standards. When installed according to Security Chimneys’installation instructions, Secure Seal meets all test requirements for horizontal and vertical, interior or exterior installations. SSID features the same construction as SSD, but with 2″ air space filled with mineral wool insulation.

FEATURES

Single and double wall for use with Categories I, II, III and IV gas-fired appliances, high-efficiency gas boilers, furnaces, booster heaters, pool heaters, water heaters, unit heaters or tankless water heaters.

Product Types

- Singte and Double Wall Systems - easily interchangeable with the use of an adapter

- Type BH Gas Vent Systems for appliances having a rated operating flue temperature of 480°F

- Type L-Vent (SSD only) for venting listed SAS or oil fired appliances certified for Type L low temperature venting

Key Features

- Laser butt-welding reinforces strength and prevents leakage while increasing durability and reliability

- Flex features a smooth inner wall that provides for no output reduction, while supporting system’s overall strength

- Built-in draw latches provide quick and easy tool-free assembly and disassembly, requiring less time on the job site

- Standard adjustable vent length provides vertical or horizontal adjustment for easy system pitching

Materials & Sealing

- 29-4C® stainless steel resists the extreme corrosive environments found in condensing boilers, assuring trouble-free operation and longer product life

- Super-ferritic stainless steel (Flex) protects against chloride ion pitting and corrosion.

- Viton-seals are more resistant than silicone against chemicals such as sulfiric acid often found in condensate

Certifications & Warranty

- Tested and listed to UL-1738 and ULC-S636

- 15-year warranty

- SecureSeal® SS-SSD-SSID 3” to 24” and LDCS-LDCD 26” to 36” Installation Instructions (English and French)

- Adjustable Length Installation Instructions (English and French)

- K&W Fixed Blade Damper Installation Instructions (English)

- Universal Boiler Adaptor Installation Instructions (English)

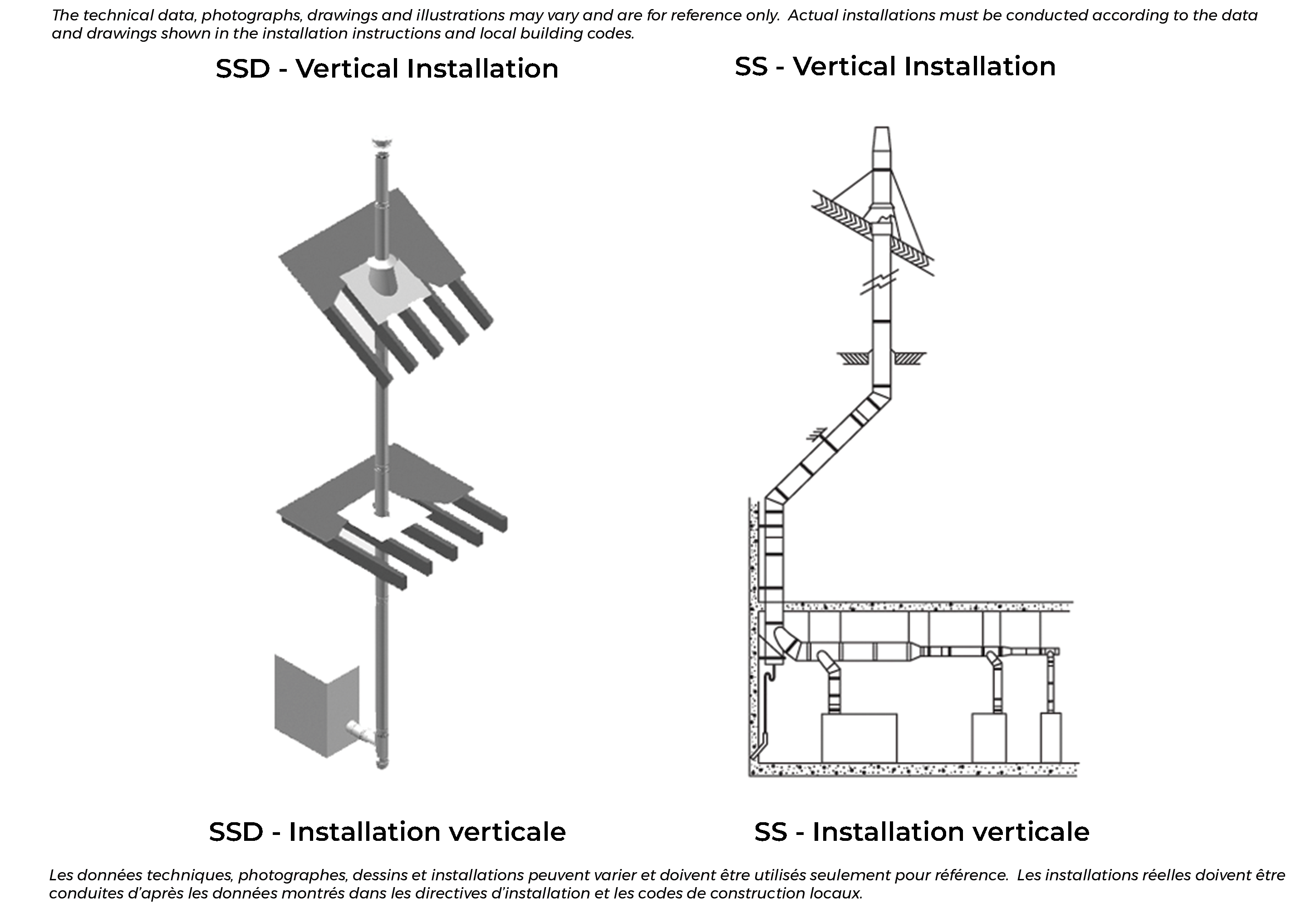

Typical Installation

- Mechanical Master Spec (English)

- SS Single Wall Specs (English)

- SSD Double Wall Specs (English)

- SSID Double Wall Specs (English)

- Flex Single Wall Specs (English)

- Material Safety Data Sheet- Fluorodyn - Viton (English)

- Material Safety Data Sheet - Novagard G 661 Lube (English)

- Chimney Sizer – Example (English)

- Secure Seal® Flex Product Discontinuation

- New Secure Seal® 48″ Lengths 05-2022

- New Product Design Secure Seal® 12-17-2019

- New Dynaflame Adapter for Camus! 09-20-2019

- New Adapters for Vaertis Dampers! 09-17-2019

- Now Available for Secure Seal® 09-20-2017

- New Fulton Vantage Boiler Adapter 07-13-2015

- New Fulton Endura Boiler Adapter 07-13-2015

- New K&W Fixed Blade Damper for Secure Seal Listed and Approved 12-15-2014

- NEW Aerco Muffler 03-27-2014